In 2019 our Creative Director Claire Hammon visited our fully traceable sapphire mine in Queensland, Australia. The company we work with has only one miner, his name is Johnny and he took Claire through the process of mining sapphires from start to finish.

Sapphire mining is different to gold mining where instead of being set up in only one place, the mining company leases an area for a period of time, digs up the area in search for rough sapphires and then fills the earth back in the same space, leaving it as they found it before moving on to a new patch of land.

First, the earth is dug up and bit by bit is taken in batches to the processing machinery where Johnny sorts through the dirt for sapphires. Once this process is complete, the earth is filled back in the mine, just as he found it.

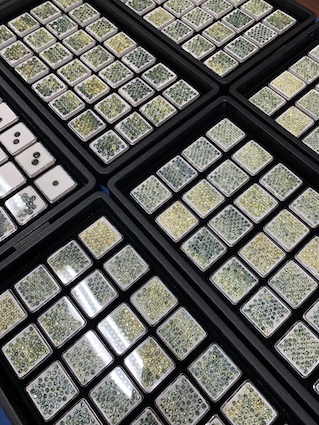

This sorting machinery is built by our miner Johnny himself and is almost like a giant sieve. This is a fairly manual process, sorting through the gravel and dirt to find the sapphires, after this the assortment of gravel and sapphires are taken to another property and put on trays, sorted manually further.

The final sorting process is on a magnetic band, which pulls out the iron from the gravel so they are left with only sapphires in the end.

The last step is putting the remaining stones and gravel in a mesh sieve & water, this process is similar to panning for gold. When shaken, the sapphires separate from the remaining same size gravel.

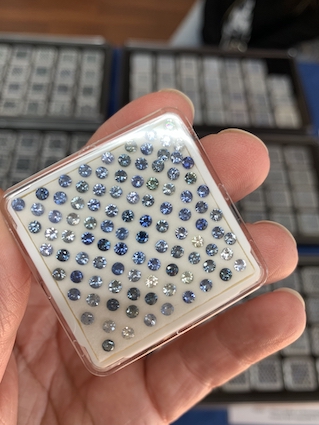

The sapphires are then put into containers to be hand graded by one person, before being sent to Thailand for cutting.